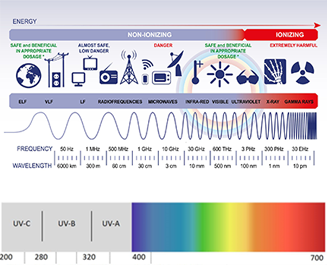

In 1903, Niels Finsen won the Nobel Prize in Medicine for his use of ultraviolet light in the treatment of tuberculosis. Since then, ultraviolet lights have been widely adapted for all kinds of uses: sterilizing hospitals, sterilizing water, germicidal lamps in food establishments, and even curing nail polish faster. If UV light is so effective, how can it be applied to improving indoor air quality for residential HVAC systems? Will it kill mold and bacteria in HVAC systems? Yes, but you need to understand the priorities of indoor air quality and the types of UV lights available for residential HVAC systems.

..............................................................................................................................!

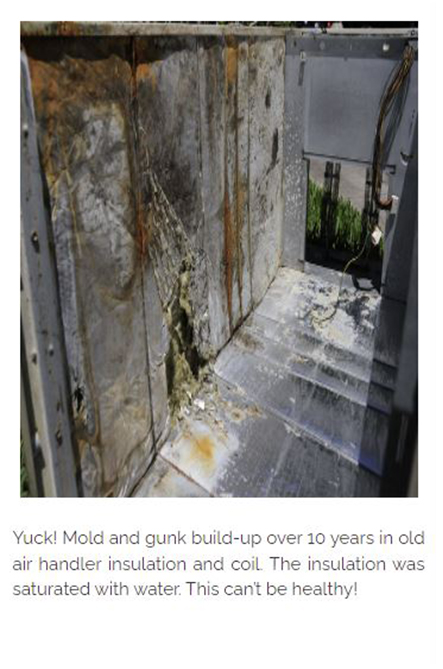

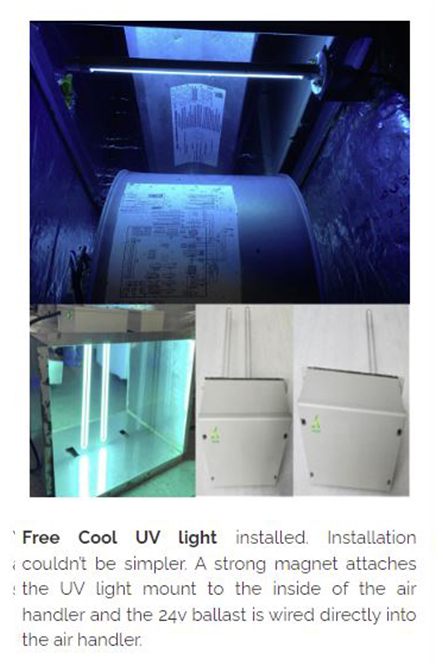

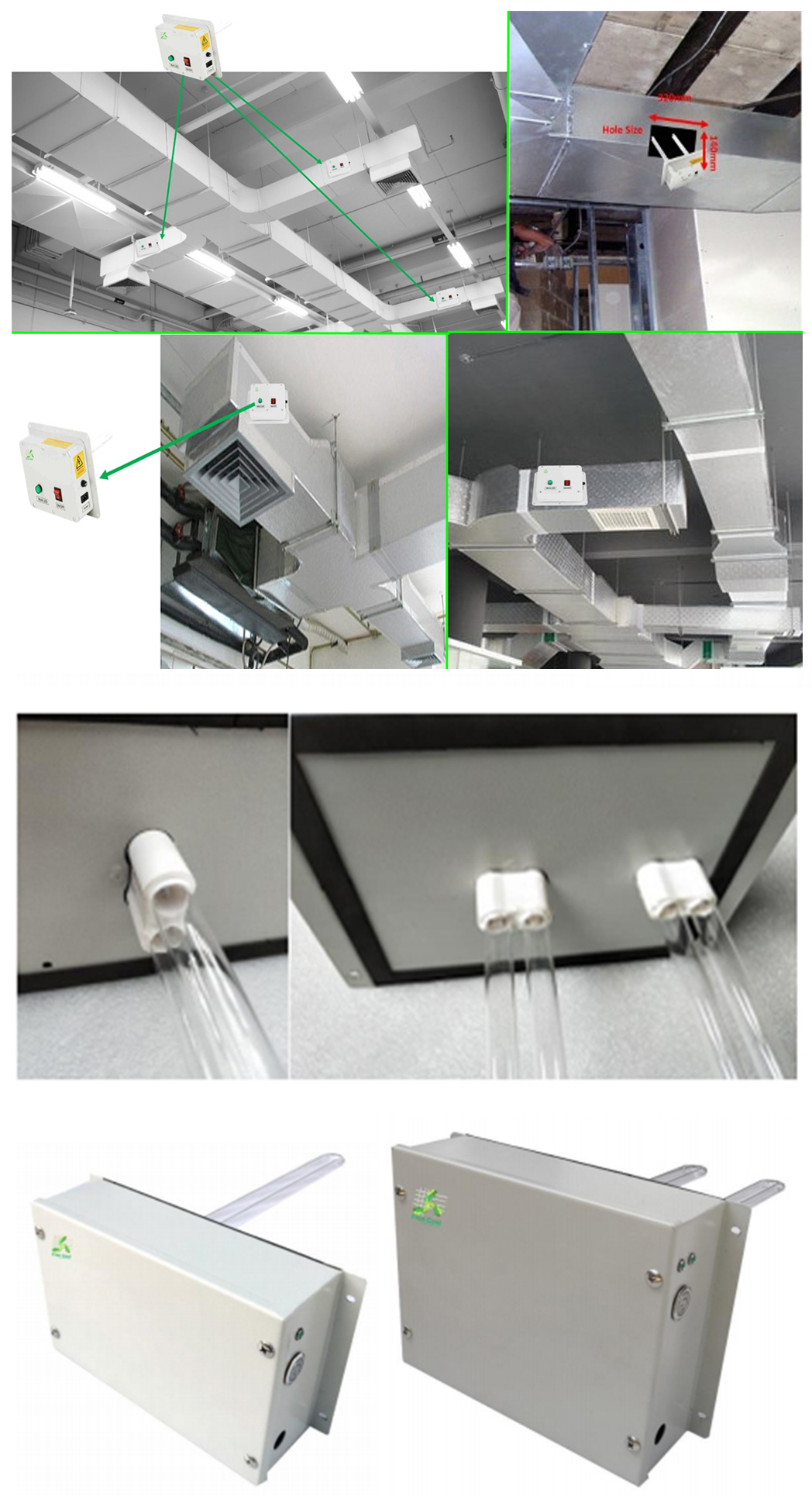

About 2 years ago, we installed a 19 SEER Lennox XC 21 air conditioner. During our most recent AC service, the technician also installed a FREE COOL HVAC UV light inside the air handler, which remains turned on 24/7. According to the technician, HVAC UV lights are very effective at controlling mold inside the air handler. All mold in line-of-sight of the UV bulb will be killed, keeping the coil mold-free. He also mentioned that several clients with respiratory problems are even able to tell if the UV bulb has burned-out due to reduced air quality. I’ll let you know if I am able to tell.

About 2 years ago, we installed a 19 SEER Lennox XC 21 air conditioner. During our most recent AC service, the technician also installed a FREE COOL HVAC UV light inside the air handler, which remains turned on 24/7. According to the technician, HVAC UV lights are very effective at controlling mold inside the air handler. All mold in line-of-sight of the UV bulb will be killed, keeping the coil mold-free. He also mentioned that several clients with respiratory problems are even able to tell if the UV bulb has burned-out due to reduced air quality. I’ll let you know if I am able to tell.

Types of HVAC UV Light

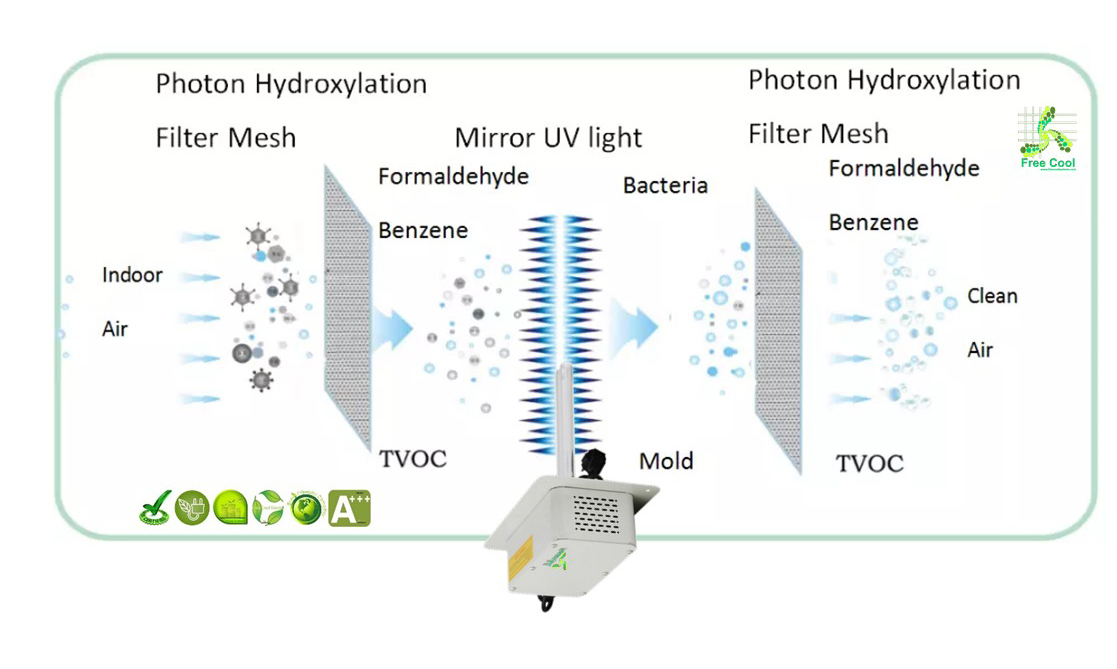

There are two types of UV lights for HAVC systems

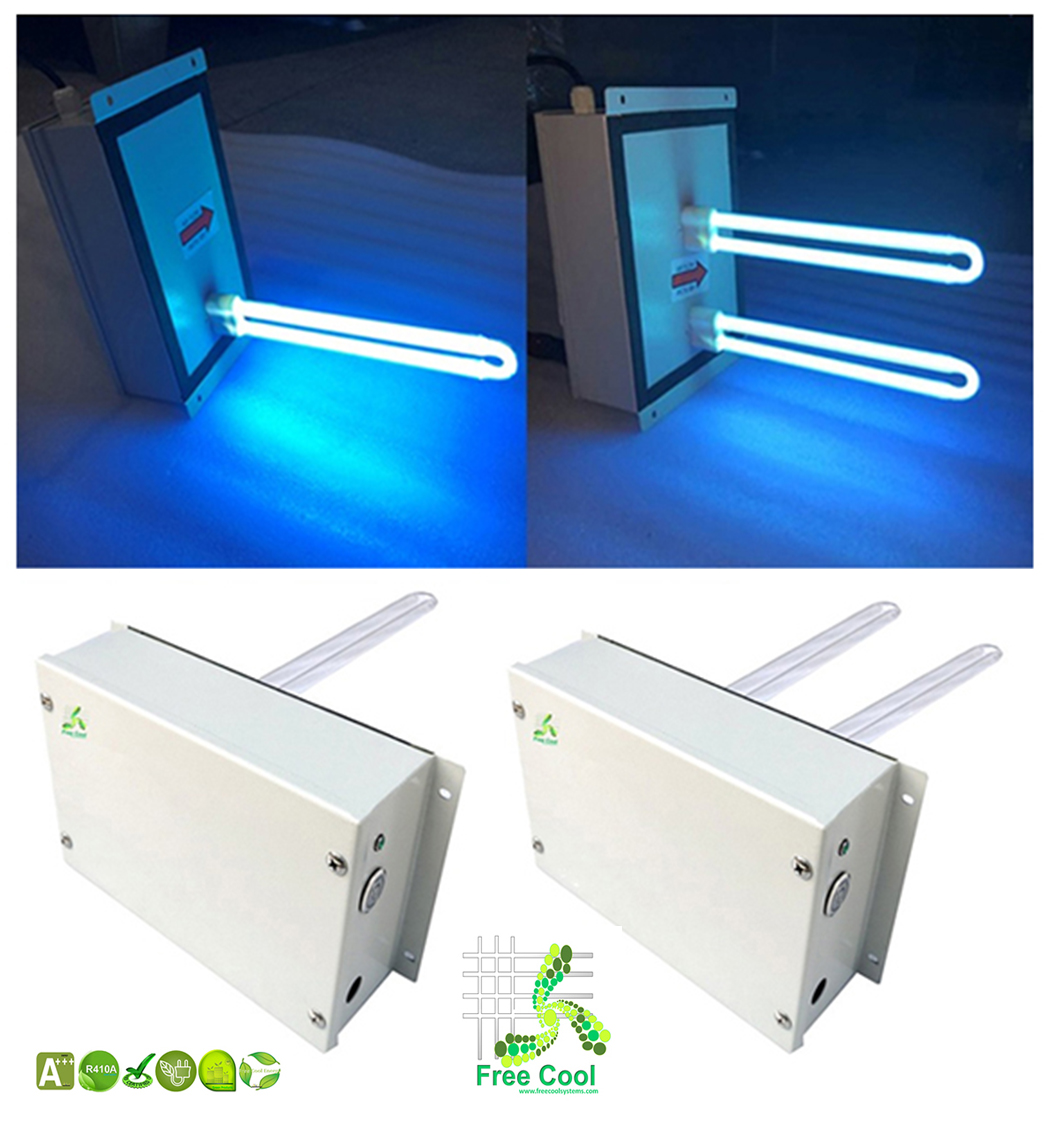

* Coil Sterilization - A "stick type" light installed inside the return air duct near that sterlizes the air handler coil. A coil sterlization UV light runs 24/7 and is the most common type of HVAC UV light. it is also most reasonably priced.

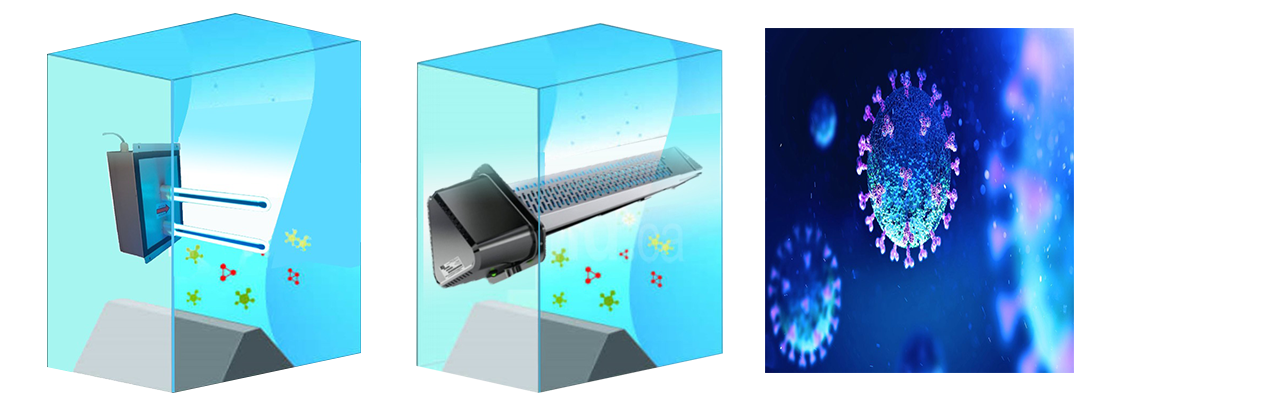

* Air Sterilization - A complete UV ligth light unit that sterilizers moving air. The UV light unit is installed in the return sir duct and cycles on with the air handler blower.

Studies Prove Effectiveness

Ultraviolet Light Effective in Hospital Infection Control – In 2012, Researchers at Duke University Medical Center used ultraviolet radiation (UV-C) to nearly eliminate drug-resistant bacteria in 50 hospital rooms, reducing the number of bacteria by more than 97%.

Effectiveness of Germicidal UV Radiation for Reducing Fungal Contamination within Air-Handling Units – In this commercial office building, and after 4 months of operation, “the fungal levels following UV operation were significantly lower than the levels in control AHUs (air handler units).”

Study shows 99.9% of coronaviruses killed by far-UVC light

The study, carried out by researchers at Columbia University Irving Medical Center, has used far-ultraviolet C (UVC) light, – In 2012, Researchers at Duke University Medical Center used ultraviolet radiation (UV-C) to nearly eliminate drug-resistant bacteria in 50 hospital rooms, reducing the number of bacteria by more than 97%.

Effectiveness of Germicidal UV Radiation for Reducing Fungal Contamination within Air-Handling Units at a wavelength which is safe for humans, to kill more than 99.9% of coronaviruses that are found present in airborne droplets. The coronaviruses are structurally similar to the SARS-CoV-2 virus that causes the novel COVID-19.

Lead author, David Brenner, Higgins Professor of Radiation Biophysics at Columbia University Vagelos College of Physicians and Surgeons and director of the Center for Radiological Research at Columbia University Irving Medical Center, said: “Based on our results, continuous airborne disinfection with far-UVC light at the current regulatory limit could greatly reduce the level of airborne virus in indoor environments occupied by people.” The research has been published in the journal Scientific Reports.

Maintenance

The Free Cool UV stick light bulb is estimated to last 9000 hours, just over 1 year.Replacement bulbs cost about $80 to 120. Replace the bulb during each annual HVAC service and maintenance is nearly effortless.